Painting

Stripe line marking services are experts in all types of road linemarkings and products. over 20 years of experience in waterborne and solvent paints to thermo and cold applied plastics and beyond

Retro Reflective Markers

from automated equipment to basic hand operated units. we have the skills and experience to accommodate any size and type of road marking or surface treatment project

Sign markings & Spotting

tailored solutions and commitment to conveying the best sydney line marking services make us an exception to other contractors.

What are the differences between products used in Line marking?

What paint is used for road line marking?

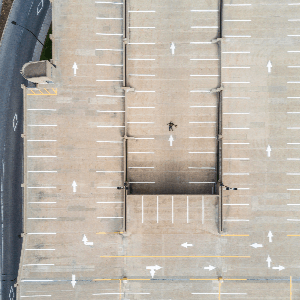

Line marking on roads involves large quantities of product they can be extremely costly. because of this some companies may use inferior products to reduce costs. consequently this greatly affects the ability of the paint to perform and last on the harsh Australian Roads and Highways.

The best quality road paints will provide a superior longevity and consistent colour throughout their life span. for that reason at Stripe Line Marking, we use the same products to mark Roads in our car parks and factory markings. as a result we can guarantee these products will provide the best longevity and quality against traffic on any surface.

road line marking paint must perform the same duties as generic paints. while withstanding the harsh and repetitive damage from vehicles. therefore Road Line Marking products must be of the highest quality. because they must with stand the most brutal and extreme conditions.

Inferior paint products used by other companies can lead to excessive wear and often don’t have the correct properties to hold onto the glass bead that gives road line markings their reflective properties

The importance of testing and trained employees is huge for consistent reflectivity of painted markings

How do road line markings glow at night?

Road line markings almost always require night-time reflective properties. This is to assist vehicles in correctly travelling in the correct part of the road.

to achieve this small glass beads are dropped on top of the paint as it is sprayed. These reflect light from the vehicles head lights back to the driver so they can clearly see the road lines. Sometimes these are assisted with the use of raised reflective pavement markers.

as a result Paint thickness is crucial to maintain retention of glass beads throughout the life of the markings. This is why all Stripe Line Marking employees are trained in the correct paint application and testing techniques.

To ensure the bead does not come out of the paint when trafficked. The paint must account for at least 60% of the height of the bead. because of this inferior quality paints can have difficulty maintaining reflectivity. Some companies neglect paint solid contents to stretch the paint further.

as a consequence the paint thickness when wet will reduce significantly once dried. therefor the dry paint will not hold the appropriate amount of bead unless applied incredibly thick when wet. however this will cause severe runs and extreme drying times

to achieve the highest quality line work Stripe Line Marking only uses the highest quality, Australian Tested and accredited paints from Road Line Marking Product experts such as Crystalite and Ennis-Flint.

One of the most difficult products to keep consistent reflectivity with is cold applied plastic. This amazing product is extremely hard and as a result beads struggle to embed in the product. manufacturers of beads have addressed this by coating the glass bead in a special silicon that assists the bead in staying in the paint.